Channelled Insole Goodyear Welt

During the late 1960s we started to innovate beyond our nailed down construction products by introducing Channelled Insole Goodyear Welt. We believe this to be the purest form of traditional Goodyear Welt shoe making that shares very similar properties, the chassis, to hand welted footwear. The first welted product we produced was a Western Boot along with our classic Hiker Boot. Over the course of almost a decade we slowly were able to source the same machines we had in our workshop 60 years ago to allow us to manufacture Goodyear Welted footwear with a heavy weight channelled insole. Hiker Boot

Hiker Boot Western Boot

Western Boot 1927 USM Insole Machine Used In Our Workshop

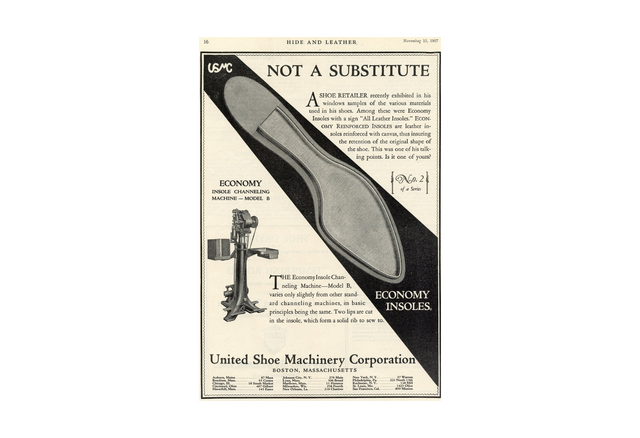

1927 USM Insole Machine Used In Our Workshop 1927 USM Machine Advertisement

1927 USM Machine Advertisement

The Chassis of our Goodyear Welt construction is made up of a heavy-weight leather insole between 5.2-5.5mm in thickness which allows for the strongest hold fast (rib) and at the same time will allow easily 10-15 years of wear with the proper care and maintenance.

The advantage of this unique form of Goodyear Welt is that the attachment point of the entire shoe is directly stitched to the insole on which your feet sit. This creates a unique opportunity for the channelled leather insole to take shape of the last bottom and mould to the shape of your feet with use. The reason is that the inside and outside feathering of the leather insole (channelling) creates a cup which matches the anatomical shape of your feet. The alternative is to use a lighter-weight insole with canvas rib to mimic the same features.

Stitchdown Construction

Implemented in the 1970s, we have been producing this type of construction for over 50 years. This type of construction is synonymous with bootmakers in the Pacific Northwest due to the simple reason of durability and ability to wick away water mud and dirt off. With the proper leather care and maintenance, resoling and re-crafting, this type of product can last a lifetime. The Chassis of our Stitchdown construction is made up of up from a heavy 5-5.5mm weight solid leather insole which holds everything into place. Both our Stitchdown and Channelled Insole Goodyear Welt share this same-weight solid leather insole. The advantage of a solid leather insole is that it will completely mould and take shape of your feet with wear. The heavier thickness allows for a longer life cycle when you resole or recraft your footwear.

During the lasting phase, we skive the upper leather by hand and turn the vamp outwards which gets sewn directly to the 4.8-5mm solid leather midsole. The second row of stitching then attaches the outsole to the midsole and vamp before the heel is finally nailed in. This creates a highly durable and robust product that is best suited for heavyweight leather.